COVID is over, but supply chain disruptions will never go away.

Mark Riskowitz

TLDR:

If it makes sense for your product category, implementing a backorder system can turn stock-outs into a chance for new revenue.

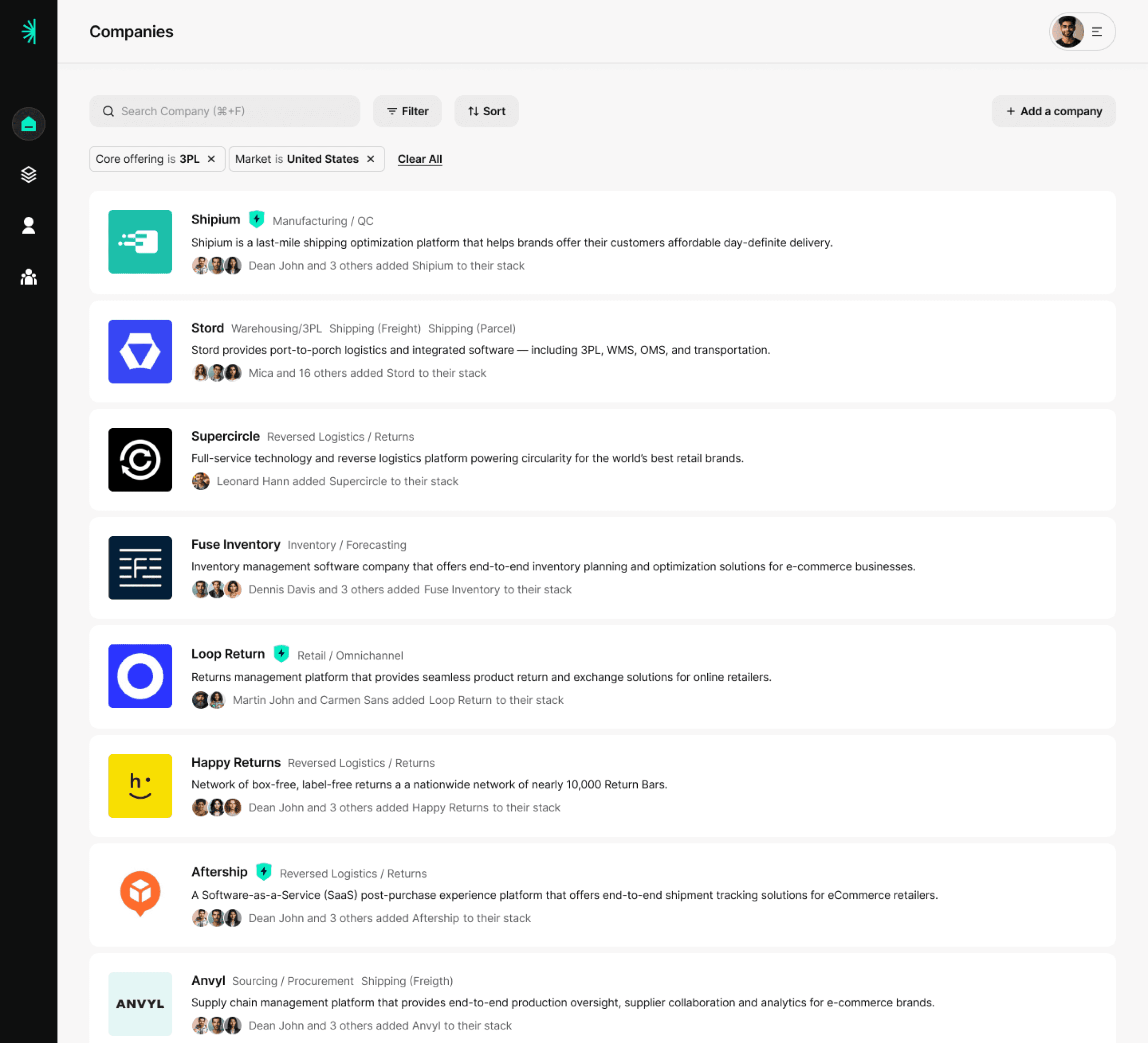

The setup

Mark Riskowitz is the VP of Operations at Caraway, a kitchenware brand. He was also the first employee, helping guide it from pre-revenue to the major player it is today in the kitchen space.

During COVID, Caraway experienced the same thing as many other brands: supply chain lock-ups, and out-of-stock inventory as a result.

Unlike other brands, Caraway implemented a unique “backorder” system that allowed customers to buy products that had run out in inventory or were launching in a few months.

What happened

The goal of the backorder system was to convert customers even when a product was out of stock.

Getting this system into place required 3 sub-projects:

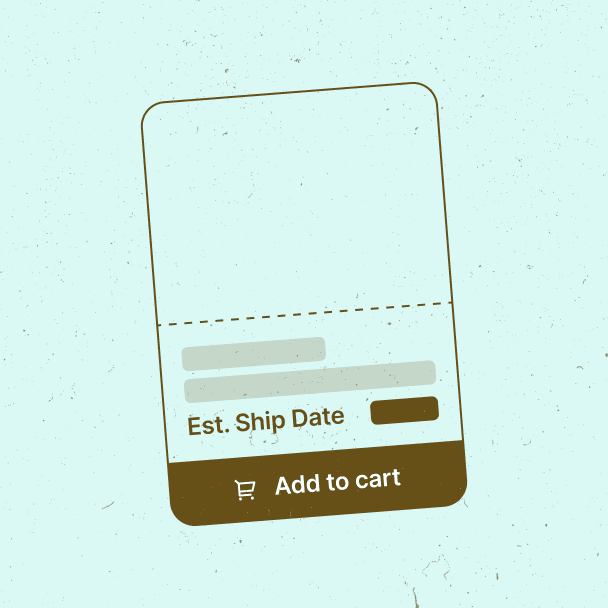

The first was user interface changes — When an item went out of stock, Caraway’s site had to still allow customers to order product and show them an accurate delivery date.

The second was new data inputs — Getting accurate delivery dates required ingesting new data from Caraway’s freight forwarder.

The third was software infra updates — Caraway’s Shopify storefront and ERP/OMS needed to be adapted to accept purchases for items that didn’t exist in inventory.

Collectively, it took less than 3 months to get a first version of the process off the ground, involving work from the supply chain and engineering teams. Apart from updates to the storefront, there was very little automation when the feature launched.

In a given year, backorder sales contribute a sizable portion revenue that would have otherwise been left on the table.

Results

👉 What started as a bad UX (i.e. stock-outs) have now become an acceptable revenue backstop in the face of supply chain delays. COVID is over, but supply chain disruptions will never go away.

👉 Cash flow improves when customers are willing to make a purchase for inventory that is still in-transit.

Key lessons

✅ Make sure your product is a good fit for backordering

A backorder system works best when you’re selling a durable product with high AOV. For things like food & beverage, consumables, and other quick-turn items, customers usually can’t afford to wait around for you to restock.

There also needs to be a differentiated product with high intent. If you’re selling a commodity, customers are more likely to switch to a substitute.

✅ For products where it does make sense — it’s never too early to implement backorders

One of Mark’s biggest regrets is simply that they didn’t implement this idea sooner. In a world of increasingly fraught supply chains, being able to sell product before it arrives in your warehouse is a game-changer.

✅ Only allow check-out when you can give a high-confidence arrival time

Just because a customer is willing to wait for their item doesn’t mean you can breach trust about the delivery date. For Caraway, this means only allowing backorders once an out-of-stock item has left the factory and is on the water/in the air. Some brands may choose to reach further upstream and make delivery promises based on POs or manufacturer delivery timelines, but each additional step in the chain adds risk of delay and therefore customer loyalty.

✅ Find the right balance of automation and manual process

The first version of Caraway’s back-order system was almost entirely manual on the back end. But this was not sustainable for the long-term — especially since Caraway has an ever-widening SKU assortment.

Mark invested time upfront to coach his team on the back-order process. Once they were up to speed, he fully empowered them to own the process. The result was that his team became an engine of continuous improvement, surfacing the parts of the system that were most problematic and time-consuming, and then pushing out suggestions and solutions.

Long term, robust automation is only possible if you have a good ERP or OMS setup. That said, you’ll never want to over-automate the system — even today, Caraway considers its process of manual checks essential.